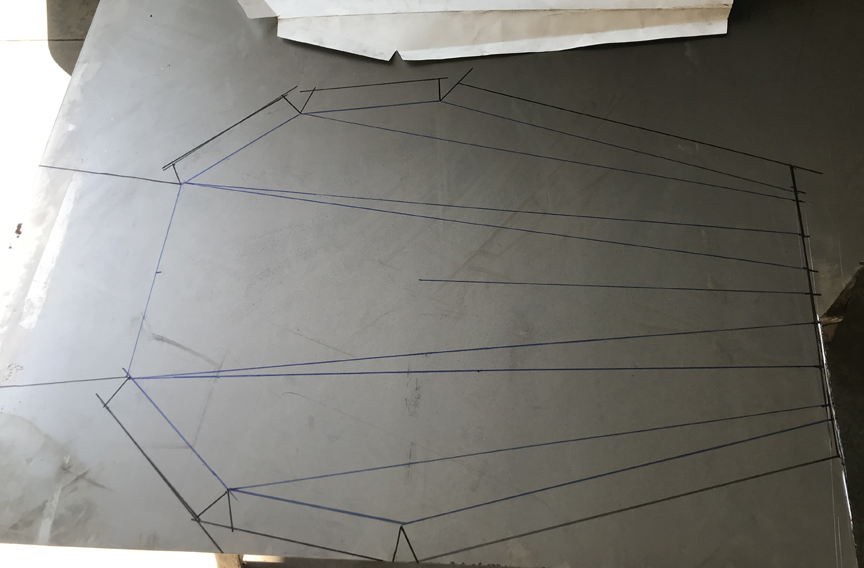

That was really a bite to get in there (it is wider than the trunk lid opening) and now I am ready to pull it back out so I can continue forming it, I tried to make so it was not a super snug fit but it turned out to be a super snug fit

I need to get in the rear seat of the car and get everything leveled out and and then start curving it down toward the gas tank, I will say I made perfect cuts around the wheel wells but of course they are not long enough (I knew they wouldn't be) but thought it would be better to keep trimming and fitting. You probably can't see much in this picture but it will all make sense eventually

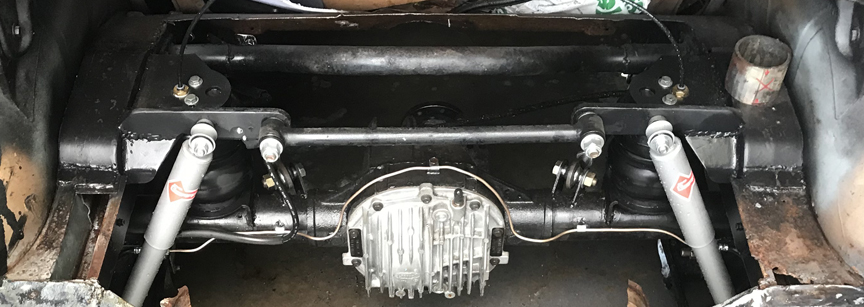

You can see on the left side I have a tab (too tall right now) going up the wheel well, where it ends the floor will start sloping down after coming back far enough to make the shocks removable under the car, I also need to cut and build wells for the air bag connections which should help some with stiffening it along with a a couple of plates to extend the frame up and seal off the top of the frame from elements and rodents. I should have plenty of room up front to mount the air tank and compressor.

Anyway moving along.

See Ya,

Mike