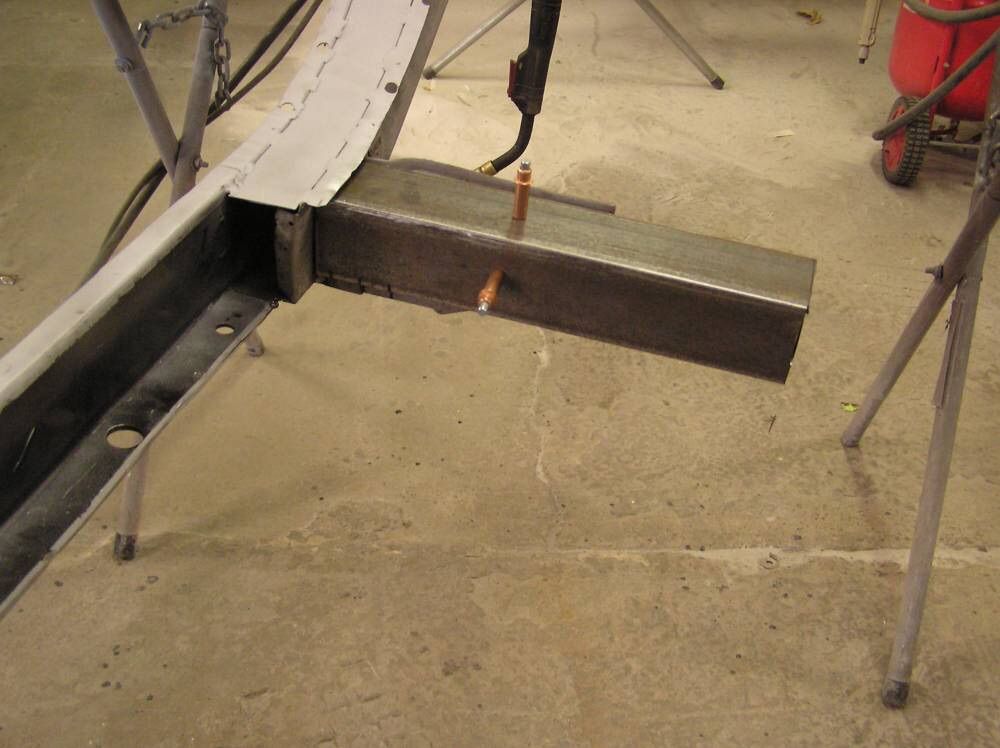

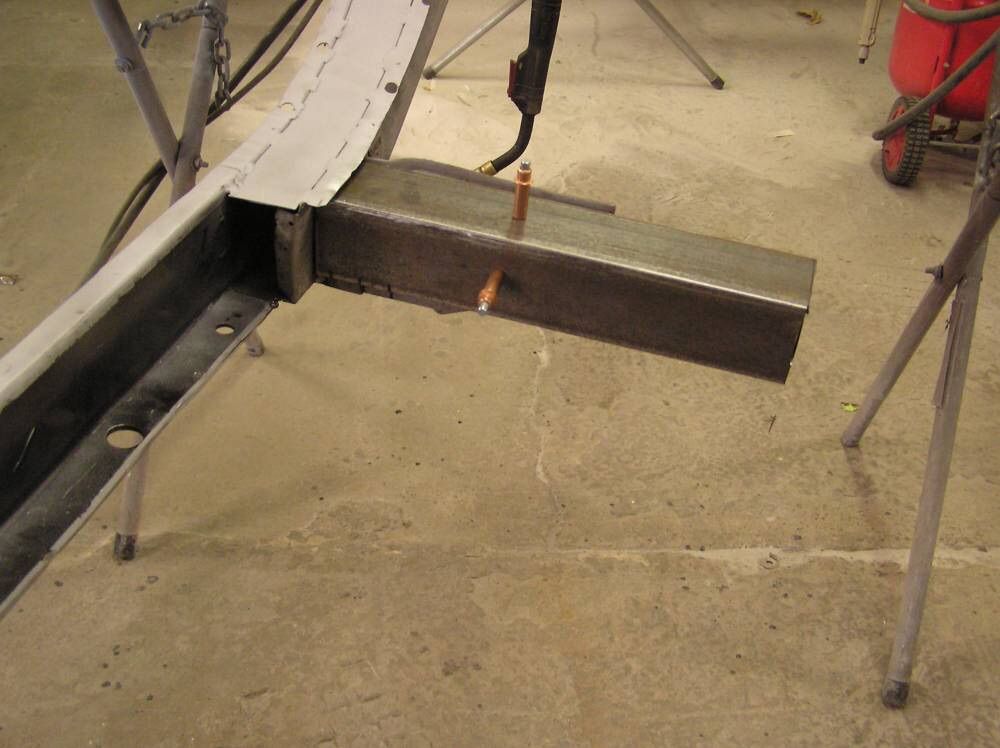

Made some more progress. Took my rear frame rail sandblasted the inside and coated inside and bottom of pieces I made to box it with POR15. When I was boxing the rail I started at the front and fitted it so it fit inside rail, then tacked the front. As I was working my way back the rail I would take my grinder and fine tune/fit the piece as I went. And tacked every 5-6 inch. I did this because I did not want the piece to push out on the rail any. I have a lot of markings to line it back up and didn't want the rail distorted??. But here is rail after boxing it. Pieces I welded in are 16 Gauge same as rail.

I needed to revamp front spring mount. Original is 1/8 inch thickness. I bought 2.5X2.5 angle 3/32. Couldn't find 1/8 that size and since it was going to be 5" longer figured the extra thickness couldn't hurt Piece is 13" long will run from inner rocker to rail over the orig mount.

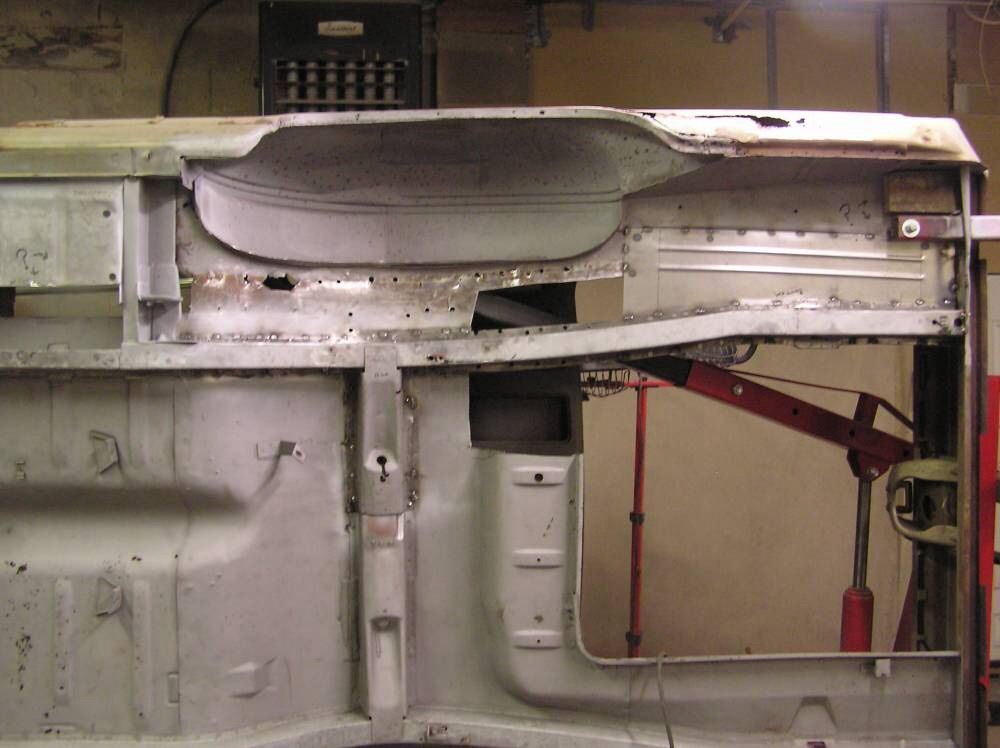

I then test fitted the rail on car make sure my measurements didn't move

The new spring mount fit nice, Just barely touching inner rocker when everything was clamped in place.

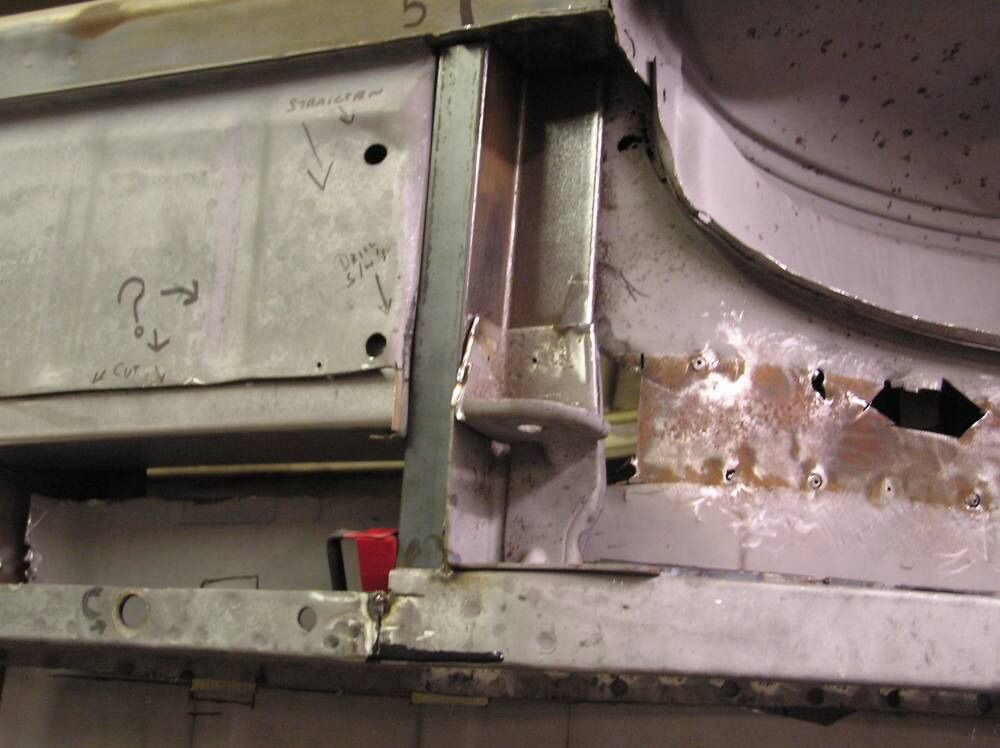

The rail is pretty much ready to be welded back on. While it was clamped on I made my template for the trunk floor. from inner rail flange out toward trunk drop. Did this with poster paper. WAY easier to cut lol

After making template. I cleaned a section of 18 gauge sheet and marked it . (Actual floor measured 19 gauge) and cut out with cut off tool.

After cutting it out I do ALL edges with angle grinder get rid of SHARP edges they suck. and then took a DA with 80 to it. Here is what it looked like fitted on car. From bottom of car and inside trunk

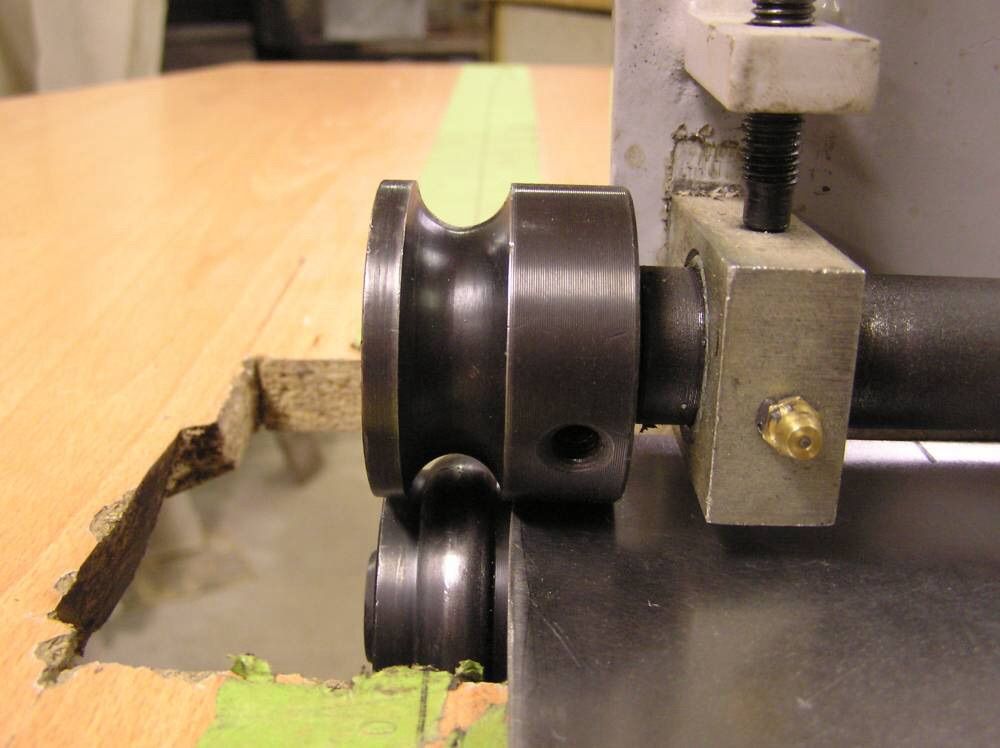

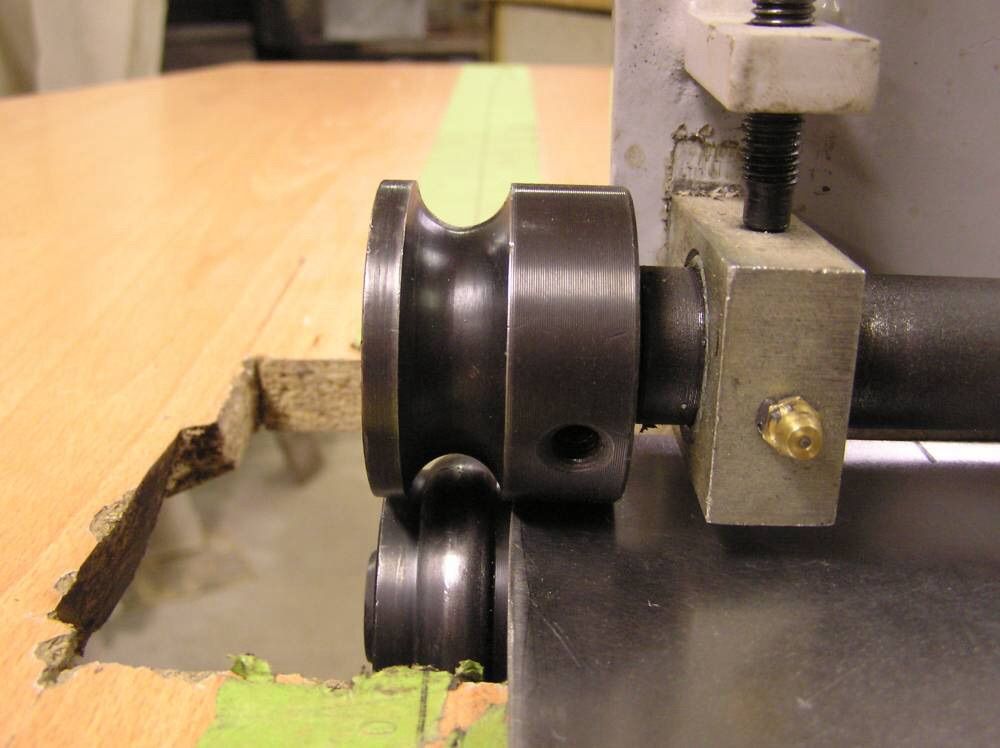

It fits nice But not big on flat sheetmetal look. Didn't want it to look like a patch being so flat. Decided to put a bead or 2 in it. Before I do the actual piece I will do a test on same thickness scrap. To make sure it will look like I want without ruining the piece. First I need to set my bead roller for the thickness 18gauge. To do this loosen tension bolt and slide in test piece between the FLATS of the rollers not the actual die? part But like this

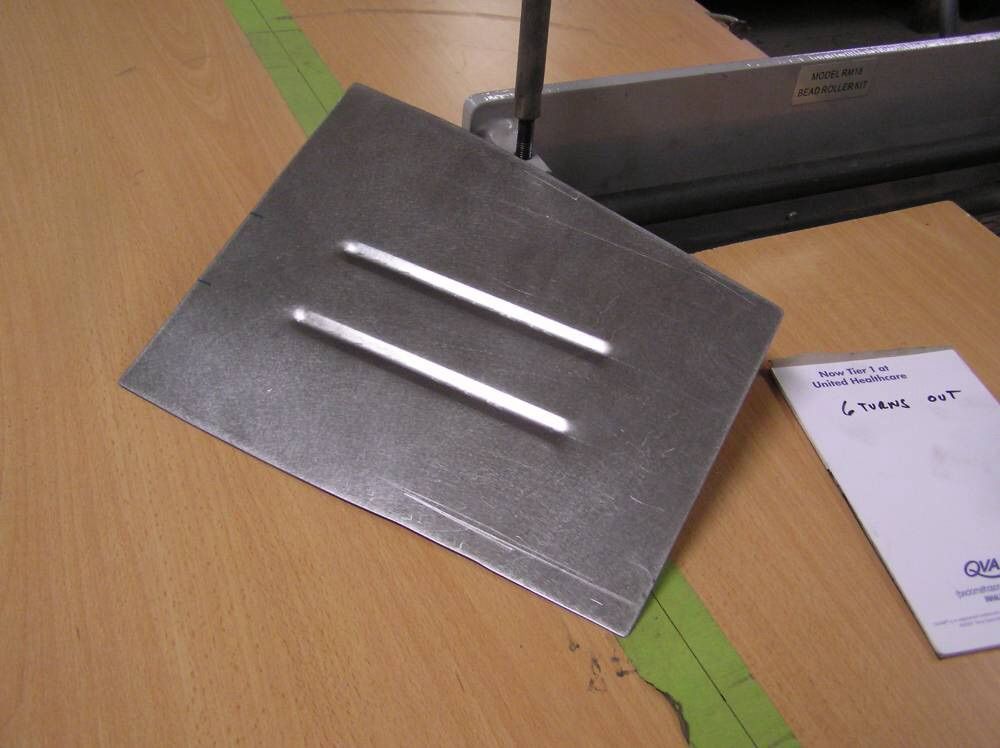

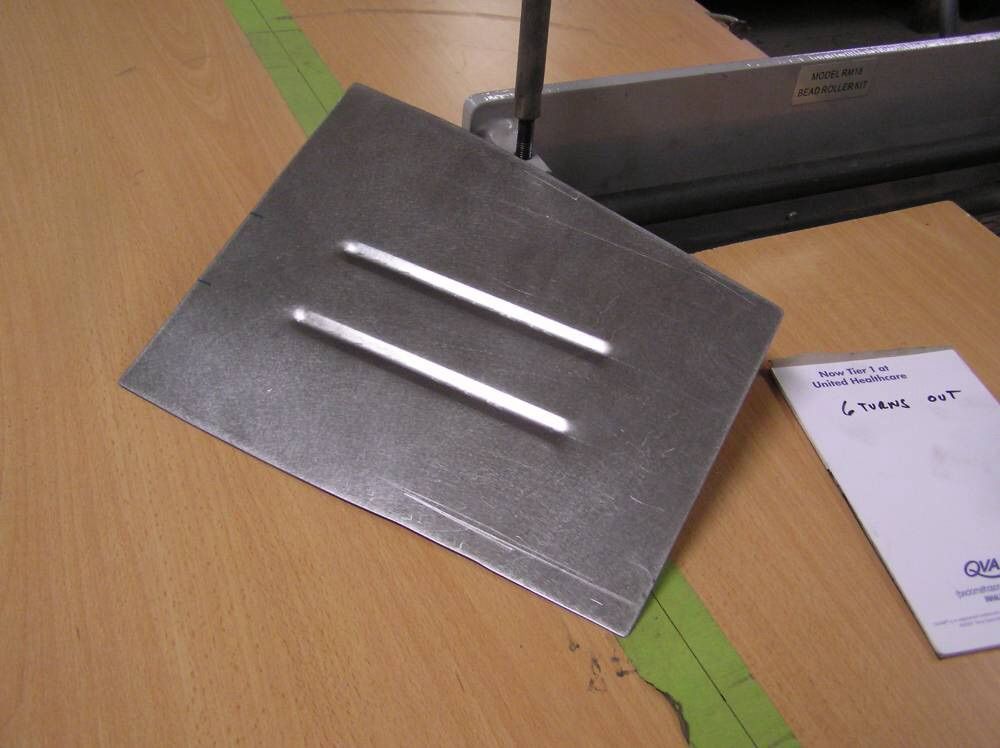

As you tighten the tension bolt make sure you can slide the metal through with your hand. If the rollers turn when you push the metal thru then back off a little. Should feel a drag on metal but rollers shouldn't spin as you push metal. I mark the position on my tension bolt, has a "T" handle. Then turn bolt out 6 revolutions. Then put sample piece in to roller. Line up mark I put on where to start bead with roller and tighten bolt 6 turns. This keeps metal from getting bowed from over tightening. Here is how sample piece turned out

Here is the good piece with first bead in it. I also clamp a piece of straight scrap on table for a guide.

Here is piece finished with the second bead rolled into it.

And here is what new pice looks like fitted on car. From in trunk and from bottom of car

Rail is pretty much ready to weld in now. Got a few little things that need fine tuning. Still not happy with the looks of the front mount But will get to that next and hopefully have this welded in soon.

Lou